Trenchless Horizontal Drilling & Pipe Installation Wollongong NSW

Avoid tearing up your site just to install a new water pipe with the help of Bedrock Drilling. Our highly experienced team has been utilising trenchless drilling practices for more than 24 years to deliver a reliable and cost-effective horizontal boring solution. This service is especially useful in urban or built-up residential areas where trenching would cause significant disruption.

Our head office is in Kiama, in the Illawarra region, but we take on projects anywhere in NSW. Call us today to get a detailed quote.

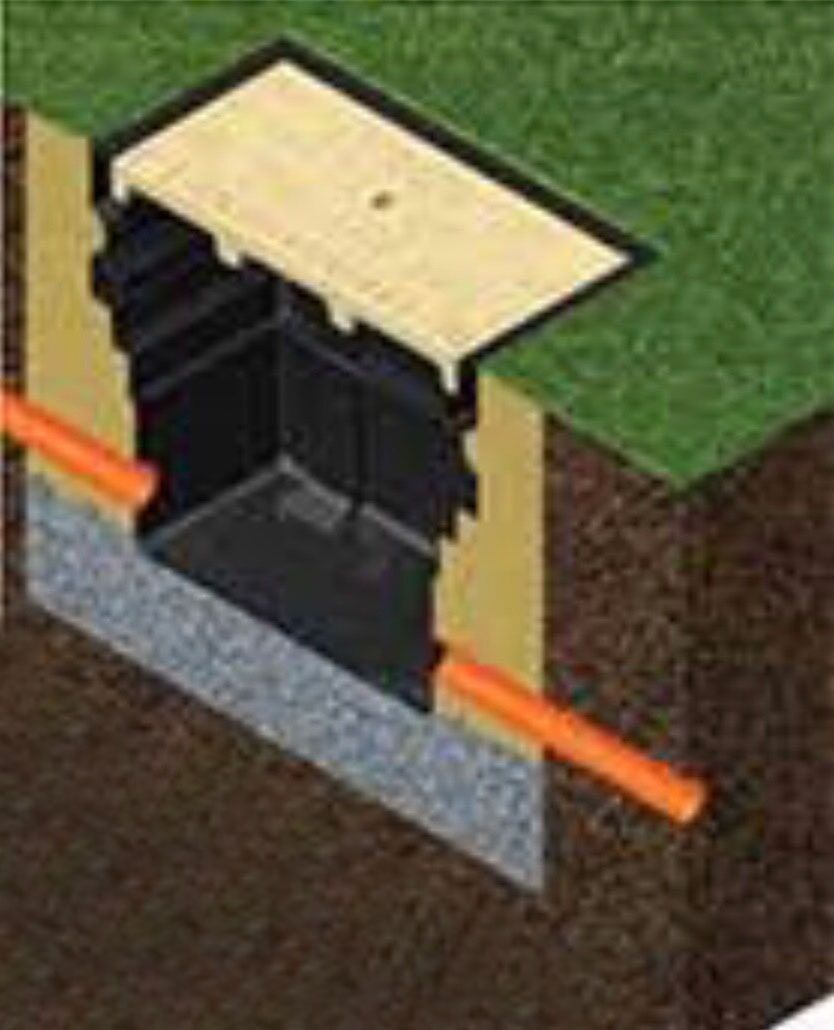

Pit Drilling

Bedrock Drilling can help you install any kind of pipeline or cable under a variety of landforms, including rivers, roads, rock, concrete, waterways, and all infrastructure.

After directional drilling has begun, pipe installation can easily be accomplished by attaching the prefabricated pipeline to the reaming assembly at the exit point. As the drill is pulled back toward the machinery, the pipe is threaded through the hole with complete accuracy.

This method can be used to install underground pipe, conduit, or cables of significant length in a fraction of the time required to trench the entire area. Our fleet includes several pipe trailers, which minimise tension and prevent damage to the pipe as it is being installed.

Please contact us to discuss your requirements and book our services at your NSW home or worksite.